Fire Stopping: 5 key things to consider in your project

Fire Stopping is a complex field that, when done poorly can have a major and negative impact on your project.

Likewise when done properly it should fly under the radar & barely raise its head in site meeting discussions as a problem.

Below we list our the top 5 key considerations to ensure Fire Stopping is a good experience on your project:

1. Consider Fire Stopping early in your design

- The earlier you consider Fire Stopping in your design the more control you have over the systems and costs

- If considered early you can co-ordinate with services routes, services materials, wall and floor systems and ensure compliance and best for client decisions are made

- Ignoring Fire Stopping in the early phase will result in poor quality, loss of quality control, loss of cost control and likely end in frustration

- A full solution register should be populated for every project individually. There is no such thing as a generic solution spec that will cater for all projects. Each project varies and therefore needs to be considered and designed each time.

- Table your solutions with Council so that they have been involved in the approval process – this will eliminate late RFI’s from council during consent stage which will risk hold ups to your project

- Table to Fire Engineer so that they have been involved in the approval process

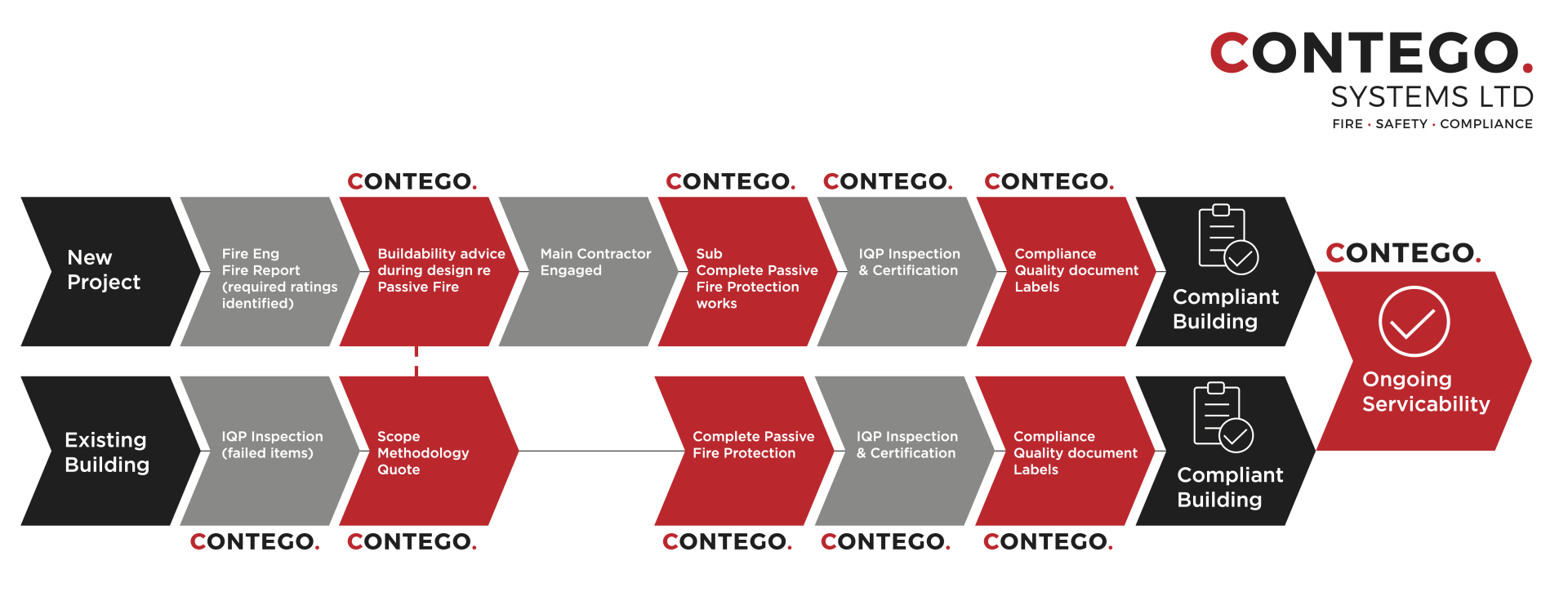

2. Engage a Specialist Fire Stopping/ Passive Fire Contractor

Specialist Fire Stopping Contractors such as Contego will have the answer to your specific problem. If they don’t then there is a good chance they aren’t a specialist

Using a specialist means:

- you will have quick access to solutions and the best way around potential issues

- you will have a smoother ride through compliance phase of the build and that there is less chance of come back issues

- Not using a specialist puts your project compliance in jeopardy & likely to fail Council, Fire Engineer or BWOF inspections down the line

- One complete package is the only way to ensure it is given the level of attention it requires.

A specialist should have the following:

i. FPANZ Membership

ii. Professional indemnity Insurance – specific to Passive Fire

iii. PS3 Approved Author status with council

iv. Trained staff (like NZQA Level 3 Passive Installer)

v. Quality Assurance systems

vi. Extensive Track record

vii. Manufacturer accreditation

viii. Recommended or vetted by your Fire Engineer and Council

3. Discuss setout of services and Fire Stopping systems before 1st fix

- To have the best control of Fire Stopping systems being installed with ease and low cost the setout should be coordinated with builder and services trades prior to 1st fix & Gib linings. This gives the best chance of accurate installations.

- Critical to ensure the correct Core hole sizes are installed

- Critical to ensure Gib, solid blocking & the like are installed

- If Fire Stopping systems are not coordinated ahead of this then it will result in reactive Fire stopping which is not cost effective and risks compliance.

4. Try to limit the systems used for a particular project

- Although not always possible to stick with one brand or one product – it is advised to limit the number of products and suppliers so that inspection and risk of installation errors are managed

- If multiple brands are used for Fire stopping it becomes very hard to inspect and verify the compliance

- Likewise if multiple brands are used for Fire stopping it becomes very easy for the installer to make a mistake and apply the wrong brand or product to a detail

- This risk is usually controlled by

- One contractor/ designated trade

- Limit the brands on site so that there is no confusion or error

5. Keep detailed and accurate records of all completed Fire Stopping

- It is imperative that every penetration treated is recorded including sticker label, location, photo, and fire stopping system used. This is a compliance record that will be relied upon for code of compliance and BWOF evidence

- Records should show sufficient detail to allow an independent person to verify compliance is achieved

- A producer statement PS3 should be provided by an Approved Author who has been pre-approved by the Council to issue PS3’s for Fire stopping including NZBC C1 – C6, & B2

- Your specialist should provide sufficient information to be carried forward with your Compliance Schedule and Specified Systems so that the IQP can inspect the building accurately